This test is designed to determine the ignition temperature of airborne dust on a hot surface. The lowest temperature of the heated impact plate at which the dust blown into the oven ignites or decomposes producing flames or explosion in less or equal than 10 seconds is stated as the minimum ignition temperature (MIT).

Minimum ignition temperature

Hot surfaces capable of igniting dust clouds exist in a number of situations in industry, such as in furnaces and burners, and dryers of various kinds. In addition, hot surfaces can be generated accidentally by overheating of bearings and other mechanical parts.

If an explosible dust cloud is generated on some uncontrolled way in the proximity of a hot surface of temperature above the actual minimum ignition temperature, the result can be a dust explosion. It is important, therefore, to know the actual minimum ignition temperature and to take adequate precautions to ensure that temperatures of hot surfaces in areas where explosible dust clouds can occur, do not rise above this value.

However, the minimum ignition temperature is not a true constant for a given dust cloud, but depends on the geometry of the hot surface and the dynamics of the cloud.

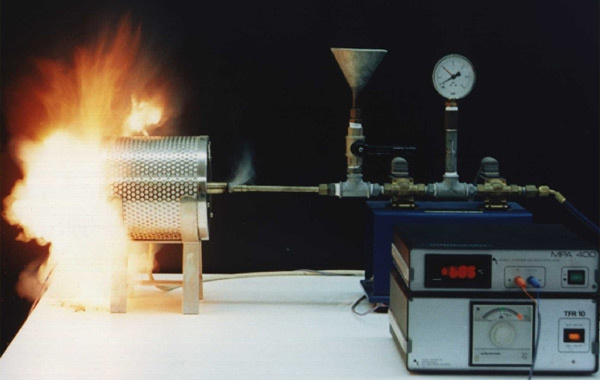

The BAM oven is a 170 mm long, electrically heated pipe oven, which is placed horizontally. Approximately in the center of the oven is a vertical impact plate, which has the shape of a scoop (diameter 48 mm, area 2000 mm²) and whose temperature is measured. A sample of the dust is blown into the front of the oven at a point axially opposite the impact plate.

The oven is heated up to a maximum temperature of 600°C. At decreasing oven temperatures the test is repeated with fresh samples at 10°C intervals until there is no ignition.

Ignition is considered to have taken place when the dust blown into the oven ignites or decomposes producing flames or explosion in less than or equal to 10 seconds. In practice this means that the flap at the end of the BAM-oven has to be lifted and flames become visible (outside the oven).

After attaining no ignitions three times in a row for a given temperature it is decided that the minimum ignition temperature of the product is the lowest temperature at which an ignition has occurred. In order to determine the lowest temperature at which ignition occurs the dust concentration has to be varied systematically.

The test is normally performed on the fraction of the powder with a particle size < 63 micron.

Due to the horizontal geometry, the BAM-furnace allows dusts that do not ignite directly in suspension, to settle on the hot internal bottom of the furnace. In this way smouldering gases can develop, which can subsequently ignite at a lower temperature than that required for direct ignition of the dust cloud. Ignition of smouldering gases normally occurs with a noticeable delay with respect to the dispersion of dust in the furnace. Because the BAM-oven test method considers such delayed ignition of smouldering gases as equivalent to ignition of the dust cloud, the minimum ignition temperatures determined by this method can be lower than those determined in the Godbert-Greenwald oven for the same dusts.

Due to the short residence time of the dust cloud inside the BAM-oven, the determination of the minimum ignition temperature in the BAM-oven is relevant to situations in which the dust cloud is shortly in contact with a hot surface. If the dust cloud is kept at a high temperature for a long period of time, e.g. in a fluidised bed, ignition can occur at temperatures below the experimentally determined minimum ignition temperature.

- EN ISO/IEC 80079-20-2:2016: Explosive atmospheres Part 20-2: Material characteristics – Combustible dusts test methods, Section 8.1

- VDI-Richtlinien 2263, Blatt 1: Untersuchungsmethoden zur Ermittlung von sicherheitstechnischen Kenngrössen von Stäuben (1990)

- Kühner AG, Safety testing equipment: Screening tests – Test procedures

- W. Bartknecht, Staub Explosionen: Ablauf und Schutzmassnahmen (1987)

- R.K. Eckhoff, Dust explosions in the process industries (1997)

- Explosion protection manual, Kluwer-Editorial