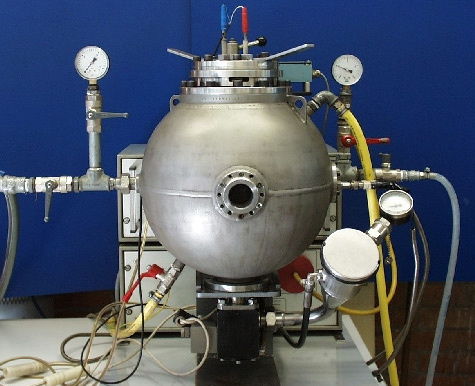

The maximum explosion pressure, the maximum pressure rise rate and the lower explosion limit are determined in a standardized test device with a volume of 20 liters. The maximum pressure rise rate (dp / dt)max measured in the 20 liter bulb can be converted to other volumes from the Kstvalue of the powder via cubic law: (dp / dt)max . V1/3 = Kst

The maximum explosion pressure and the Kstvalue describe the explosion behavior of a flammable dust / air mixture in a closed system. The explosion limits indicate the range of dust concentrations within which an explosion is possible. In general, only the lower explosion limit is determined.

By means of the measured combustion time in the 20 litre-sphere, a value for the minimum ignition energy can be estimated.

Maximum explosion pressure

Most process equipment will not be sufficiently strong to withstand the typical pressures generated by unvented dust explosions. In principle, strengthening of the equipment can prevent it from bursting, but in general the structures required for achieving the sufficient strength will have to be so heavy that this approach is not generally recommendable, neither from the point of view of capital cost nor with respect to running and maintaining the plant. Exceptions are cylindrical dust extraction ducting, which can be made pressure resistant with reasonable wall thicknesses, and certain types of equipment which is heavy anyway, such as some mill types.

It nevertheless happens that the concept of fully pressure resistant process plant is adopted, e.g. when the powders are highly toxic and therefore in no circumstances can be admitted to outside the equipment. In such cases it is important to know the highest pressures to be expected, should a dust explosion occur within the equipment.

Maximum rate of pressure rise

Industrial enclosures such as conventional process equipment, are normally far too weak to withstand the pressures exerted even by only partly developed, confined dust explosions. Consequently a primary objective of fighting an explosion after it has been initiated, is to prevent the build-up of destructive overpressures.

Regardless of which protective technique is adopted, the violence of the dust explosion, i.e. the rate of heat generation inside the enclosure where the explosion is initiated, is a deciding factor as to whether a given protection system will perform adequately.

Lower explosion limit

For a given type of explosible dust, dispersed as a cloud in air, there is a well defined minimum quantity of dust per unit volume of air below which the dust cloud is not able to propagate a flame. In theory, therefore, one could eliminate the possibility of dust explosions by ensuring that the dust concentration does not exceed this lower explosion limit.